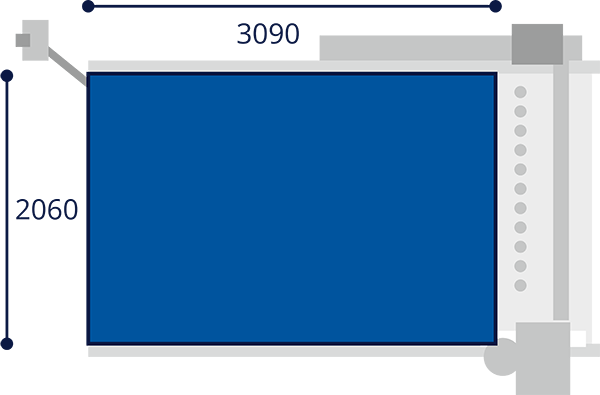

| CNC milling | Working area | Materials | Drawing file | Price | CNC Milling possibilities |

CNC Milling

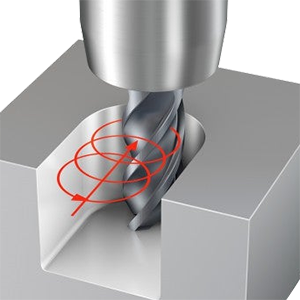

CNC milling enables efficient and high precision cutting of parts from a wide range of sheet materials. CNC milling technology allows you to mill materials that cannot be cut with laser cutting, such as PVC, water- and moisture-resistant plywood, aluminum, composite materials.

The entire process from drawing to product is quick and usually requires relatively little machine setup. Therefore, it is possible to manufacture individual objects as well as serial production. The advantages of our milling machine are best suited in the production of parts from sheet materials, while the milling of three-dimensional parts is successfully possible thanks to the use of special Siemens NX software. Ask for an offer for CNC milling, we will respond quickly and give advice if necessary.