Plexiglas

Plexiglas is a great material for making durable and good-looking products.

Plexiglas processing methods

The laser studio will use Plexiglas sheets with a width of 2050 x 3050 mm. We mainly use Plexiglas manufactured in Germany at the RÖHM factory. Different thicknesses are available, as well as coloured and satin plexiglass.

Laser cutting of plexiglass

Laser cutting of plexiglass

Laser cutting allows you to achieve a very precise and high quality cut line. The transparent laser-cut plexiglass remains glossy on the cutting edge.

CNC milling of plexiglass

CNC milling of plexiglass

CNC milling is another way of cutting plexiglass. The edge of the pieces cut by this method will remain precise and of high quality, with a matt finish. Material with milled edges is slightly more adhesive, especially when thicker material is used.

Plexiglas bonding

Plexiglas bonding

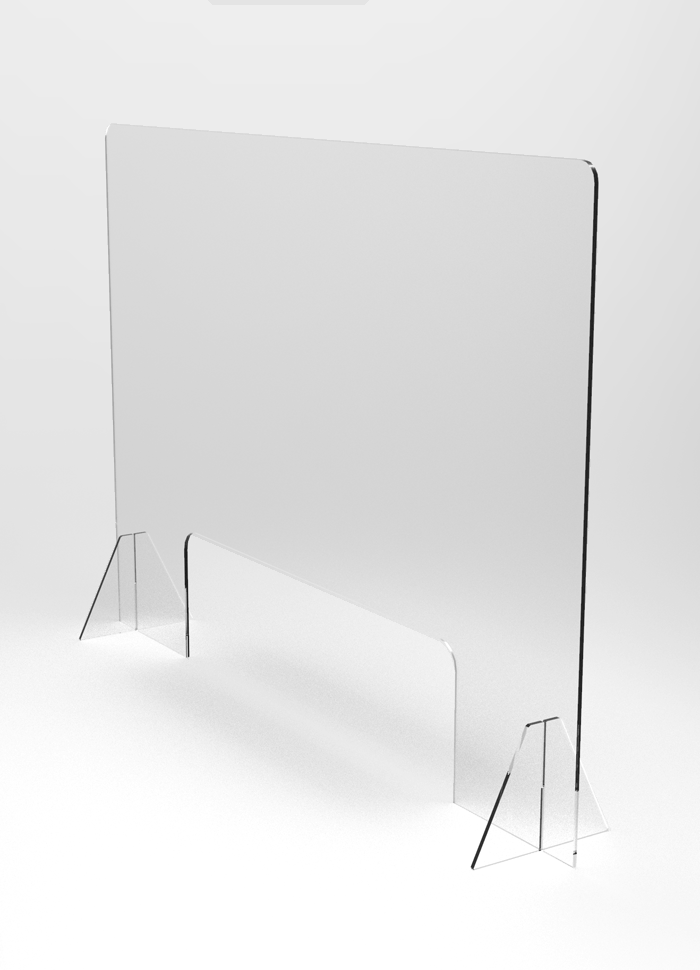

Plexiglas is highly adhesive. The glue itself is completely transparent. In our laser studio, we manufacture adhesive products according to your drawings and also as ready-made products, which are available in our online shop.

Bending the Plexiglas

Bending the Plexiglas

Plexiglas can be bent in different ways. The most common pressure is 90 degrees, but you can also bend to other angles. A smooth printing or Plexiglas curved surface is also feasible, but you need to prepare the bending moulds to achieve a good result. It makes sense to produce such bent parts in series so that the cost of the moulds is spread over several finished products.

Plexiglas types

Plexiglass in different finishes is available:

- clear Plexiglas;

- opaal pleks;

- coloured Plexiglas;

- satin plexiglass

Clear or transparent Plexiglas

are available in stock at Laser Studio. The main thicknesses available are 2, 3, 4, 5, 6, 8, 10, 12, 15, 20 mm. Thicker materials are also available, but the greater the thickness, the more expensive it is to process and cut.

Opaalpleks

is commonly used in the manufacture of luminaires and light boxes. More and less translucent types are available. That is, a less translucent opal sheet is whiter and scatters light better, while a more translucent type may allow the light source to shine through somewhat more. Available in a range of thicknesses from 2 mm – 20 mm.

Coloured Plexiglas

is more expensive, but it allows you to make stylish products. There is a smaller range of material thicknesses: 3 mm is the main material used, but thicker materials are also available.

Satin plexiglass

has a matt surface and is usually translucent. The basic material thicknesses are 4 and 6 mm.

Plexiglas alternatives

PET is also called AXPET, PET-G. This material is used, for example, to make drinks bottles. PET can be cut by laser cutting and CNC milling. In addition, it is bendable and very good vacuum formable, but not adhesive. PET is more flexible than Plexiglas, so the thinner PET can be used to make shatter-resistant flayer pockets, product trays, advertising holders and more. The main thicknesses of the material are 1; 1,5; 2 and 3 mm. From the colour range you can get clear and opal PET.

Polycarbonate is a very strong material. It can be milled and bent, but not as well as Plexiglas. Unfortunately, polycarbonate cannot be laser cut or glued. To get is a bright green and opal polycarbonate.

Polystyrene is a good material for vacuum moulding, and is available in white and primary colours.

PVC is a weaker material, but can be a cost-effective alternative to Plexiglas.

Use of Plexiglas

PRODUCT HOLDERS

Infographics

Info platforms

Storage boxes

Safety glasses

Plexiglas price

In the laser studio, we can cut Plexiglas parts according to your drawings. We have the material on site or available within a few days. Laser cutting, CNC milling and polishing of the cutting edge are possible. Ask for a price for cutting Plexiglas:

I’m looking at the price of cutting Plexiglas: