Laser cutting, CNC milling,

different plastic processing options

are our everyday tasks. We manufacture products and components according to your drawings and, if necessary, consult on materials and technological possibilities. Laserstuudio has a long experience in laser cutting of light materials, gluing of plastic parts, bending and creating plastic products.

Materials

We can use a wide range of materials when designing and producing our products. Different lightweight materials are perfect for laser cutting: plastics, wood, textiles, paper and much more. CNC milling allows us to cut aluminum and brass as well.

Stock materials

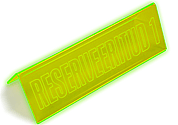

Acrylic glasses with thicknesses from 3 to 10 mm and PET with thicknesses from 1 to 2 mm are available on site. It is also possible to use white PVC with different thicknesses. Colored acrylics and PVCs are usually available in a few days, but it is always worth it to check the availability beforehand.

Drawing file

To complete your order quickly, it is important for us to get a proper vector file. In general, vector graphic formats such as dwg, dxf, ai, cdr, and pdf are suitable. The file should be dimensionedhave a ratio of 1:1.

Do not hesitate to contact our project managers for advice.

Equipment

Laser cutting

Laser cutting is the right technology if you need the best results and professional-looking products and details. Laser cutting provides great accuracy and the process from the idea to the final result will be simple.[fusion_portfolio layout=”grid” picture_size=”auto” boxed_text=”unboxed” filters=”no” columns=”4″ column_spacing=”0″ cat_slug=”laserl6ikus” exclude_cats=”” number_posts=”6″ offset=”” excerpt_length=”35″ strip_html=”yes” carousel_layout=”title_on_rollover” scroll_items=”” autoplay=”no” show_nav=”yes” mouse_scroll=”no” animation_type=”0″ animation_direction=”down” animation_speed=”0.1″ animation_offset=”” class=”” id=””][/fusion_portfolio]

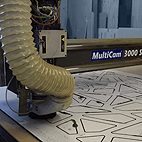

CNC Milling

CNC milling technology makes it possible to process a large variety of sheet materials efficiently and with high accuracy.

The whole process is quick from the vector file to the final product, and usually requires relatively little machine setup. It is possible to produce individual objects as well as a series of products. CNC milling allows to cut materials which are impossible to cut with laser such as PVC, water and moisture-resistant plywood, aluminum, composite materials. The advantages of our milling machine are best suited for the milling of sheet materials, but it is possible to successfully produce 3D parts thanks to the use of special Siemens NX software.[fusion_portfolio layout=”grid” picture_size=”auto” boxed_text=”unboxed” filters=”no” columns=”4″ column_spacing=”1″ cat_slug=”cnc_freesimine” exclude_cats=”” number_posts=”8″ offset=”” excerpt_length=”35″ strip_html=”yes” carousel_layout=”title_on_rollover” scroll_items=”” autoplay=”no” show_nav=”yes” mouse_scroll=”no” animation_type=”0″ animation_direction=”down” animation_speed=”0.1″ animation_offset=”” class=”” id=””][/fusion_portfolio]

Vacuum forming

Vacuum forming makes it possible to give a plastic sheet a 3d shape. The plastic sheet is heated and pulled onto the mold with vacuum. This technology is well suited for the serial production of 3d elements, where the price of the molding form is divided into many final products.[fusion_portfolio layout=”grid” picture_size=”auto” boxed_text=”unboxed” filters=”no” columns=”4″ column_spacing=”1″ cat_slug=”vaakumvormimine” exclude_cats=”” number_posts=”8″ offset=”” excerpt_length=”35″ strip_html=”yes” carousel_layout=”title_on_rollover” scroll_items=”” autoplay=”no” show_nav=”yes” mouse_scroll=”no” animation_type=”0″ animation_direction=”down” animation_speed=”0.1″ animation_offset=”” class=”” id=””][/fusion_portfolio]

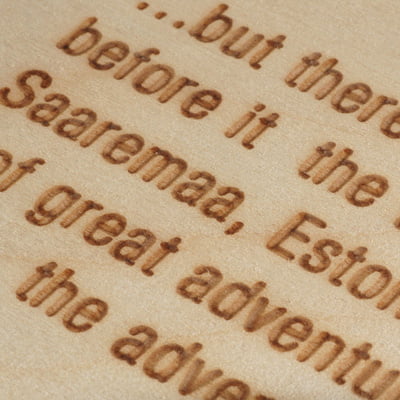

Laser engraving

Laser engraving allows to transfer texts, logos or other design elements to the product surface.

In the case of cutting architectural models, it is possible to engrave graphical elements on the surface: doors, windows, tiles and so on. It is popular to engrave the company logo on the booklet stands. Laser engraving can not be applied to metal, but can be, for example, to wood, leather or acrylic. It is possible to engrave painted or anodized metal. In that case, anode or paint will removed from the material surface. With wood and plywood, slight variation in the tone of the engraved finish can occur from sheet to sheet, as they are natural materials. Tone of wood, grain line and density and moisture content all have an impact on the engraving tone. Wood and plywood can be engraved with an excellent clarity from a dark brown to light brown tone.[fusion_portfolio layout=”grid” picture_size=”auto” boxed_text=”unboxed” filters=”no” columns=”4″ column_spacing=”1″ cat_slug=”lasergraveerimine” exclude_cats=”” number_posts=”8″ offset=”” excerpt_length=”35″ strip_html=”yes” carousel_layout=”title_on_rollover” scroll_items=”” autoplay=”no” show_nav=”yes” mouse_scroll=”no” animation_type=”0″ animation_direction=”down” animation_speed=”0.1″ animation_offset=”” class=”” id=””][/fusion_portfolio]